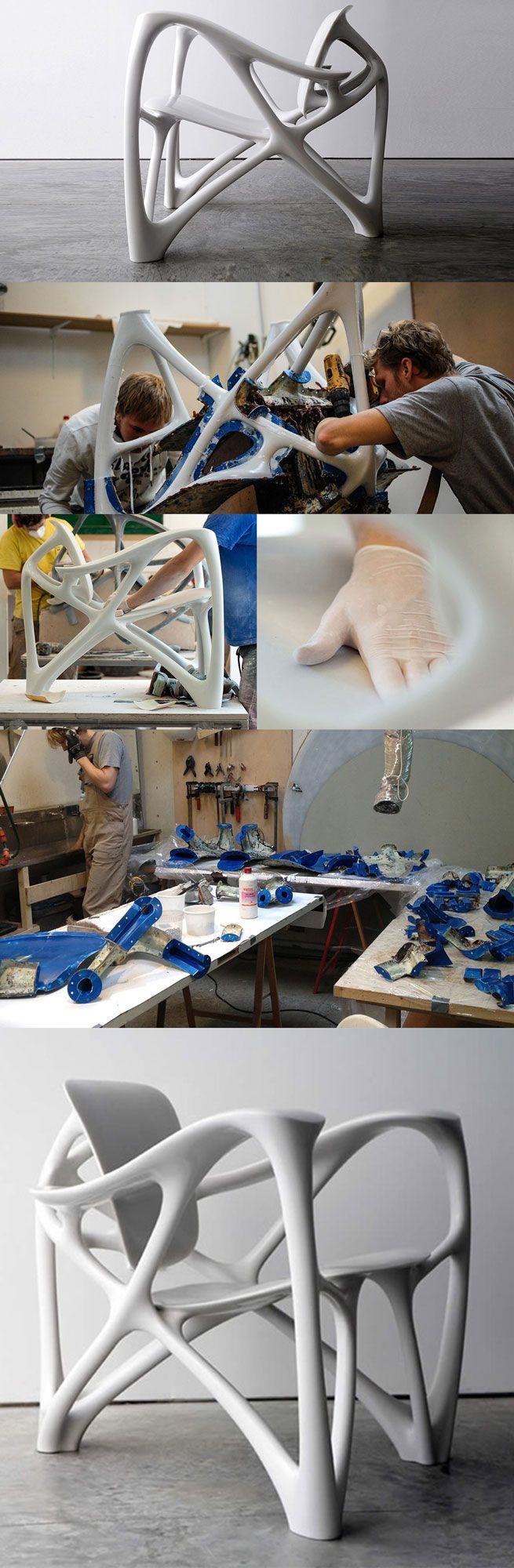

Around this time, 3D printing received a huge amount of buzz. The possibilities were still rather limited, however, and the few people who began working with it had only one material to choose from. Considering the work it took to create the mold for the Bone Chaise, we thought it’d be interesting to use 3D printing for the production of complex molds. This would give us the formal freedom of 3D printing, but we could still use high-quality materials. With regard to the design of the White Armchair, experiments with casting resins gave us the idea to grind down old bone-china coffee cups and subsequently mix them with casting resin. To our amazement, blending in the porcelain cups worked really well, but what was supposed to become a porcelain-like bright material came out a drab, grey good-for-nothing cube. Eventually, we ended up with a mix of white Carara marble powder (a by-product of the marble industry) and casting resin. This resulted in a beautiful, porcelain-like material. I remember what a huge gamble ordering the expensive mold was—since none of us had any experience with such a thing and we had no idea whether it would work. In the end, it proved to exceed all our expectations. The White Armchair is cast in a single piece in a 3D printed 91-part mold.

The Armchair is part of the permanent collection of the High museum of Art, Atlanta, USA

Making of Arm Chair from anita star on Vimeo.